2025-09-27 20:24:51

In the entire operation process of a 3015 fiber laser cutting machine, the nozzle, though small in size, plays a crucial role. It not only affects the quality and precision of the cut but also impacts the lifespan of the cutting head and overall production efficiency. Choosing the right nozzle, using it correctly, and maintaining it properly are essential to ensuring long-term, stable machine performance. This article explores the functions, selection, and maintenance of fiber laser cutting nozzles in detail.

🔥🔥Core Functions of the Nozzle

✅Protecting Optical Components

During cutting, the nozzle effectively blocks molten spatter and debris from rebounding into the cutting head, preventing contamination or damage to protective lenses and extending the service life of the laser head.

✅Optimizing Cutting Quality

By regulating the direction and flow rate of the assist gas, the nozzle ensures a more concentrated and stable gas stream, which facilitates the removal of molten material and produces smooth, precise cut edges.

✅Stabilizing the Cutting Process

The nozzle guarantees uniform gas distribution, which enhances piercing stability and helps prevent defects such as burrs, dross, or rough cut surfaces.

🔥🔥Relationship Between Nozzle Condition and Cutting Quality

The condition of the nozzle has a direct and significant impact on cutting results:

✅Deformation → Uneven airflow, resulting in rough cut edges.

✅Blockage → Difficult piercing or interrupted cutting.

✅Excess residue → Beam offset, leading to reduced cutting accuracy.

To avoid these issues, operators must:

✨Clean regularly to remove debris and residue;

✨Replace promptly when damage or wear occurs;

✨Recalibrate accurately to maintain proper alignment between the nozzle and cutting head.

🔥🔥Key Considerations in Nozzle Selection

✅By Diameter

Small-diameter nozzles: Provide higher gas velocity, ideal for thin-sheet, high-speed cutting with fine and smooth edges.

Large-diameter nozzles: Deliver lower gas velocity, suitable for thick-sheet, low-speed cutting with enhanced stability.

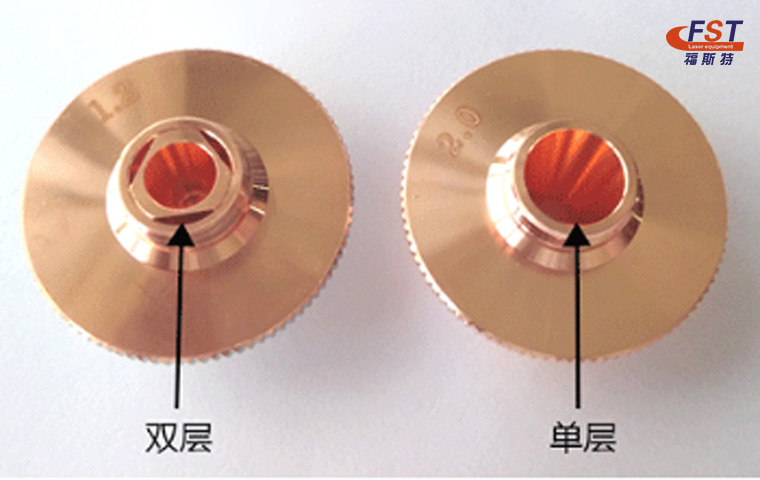

✅By Structure

Single-layer nozzles: Commonly used for stainless steel cutting; produce concentrated gas flow and clean, smooth cuts.

Double-layer/multi-layer nozzles: Typically applied in carbon steel cutting; distribute gas more evenly for stable cutting performance.

🔥🔥Nozzle Replacement and Adjustment Procedure

✅Unscrew and remove the worn nozzle, clean the interface area;

✅Install the new nozzle securely into the connector;

✅Perform capacitive calibration to ensure proper alignment and height accuracy of the cutting head;

✅Conduct a test cut to verify stable cutting performance.

Conclusion

For a 3015 fiber laser cutting machine, the nozzle, though seemingly a minor component, directly determines cutting precision, equipment longevity, and production efficiency. Proper nozzle selection, routine maintenance, and timely replacement are critical to unleashing the full potential of a laser cutting system, ensuring both high efficiency and long-term stability.

👉 Interested in learning more about our laser cutting, welding, or cleaning machines? Feel free to contact Us:+86 15314155887—he’s ready to provide expert guidance and the ideal solution for your needs.