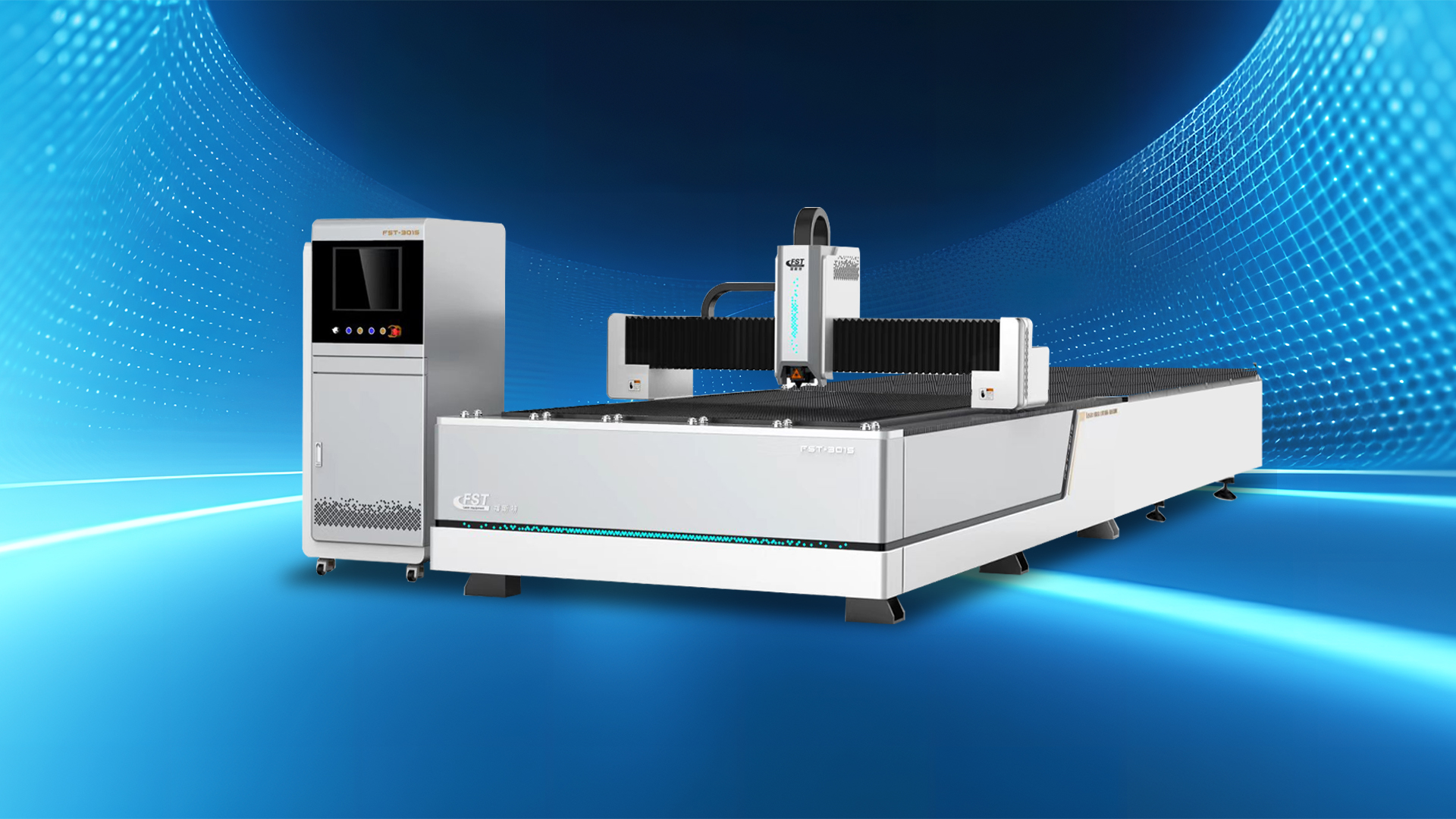

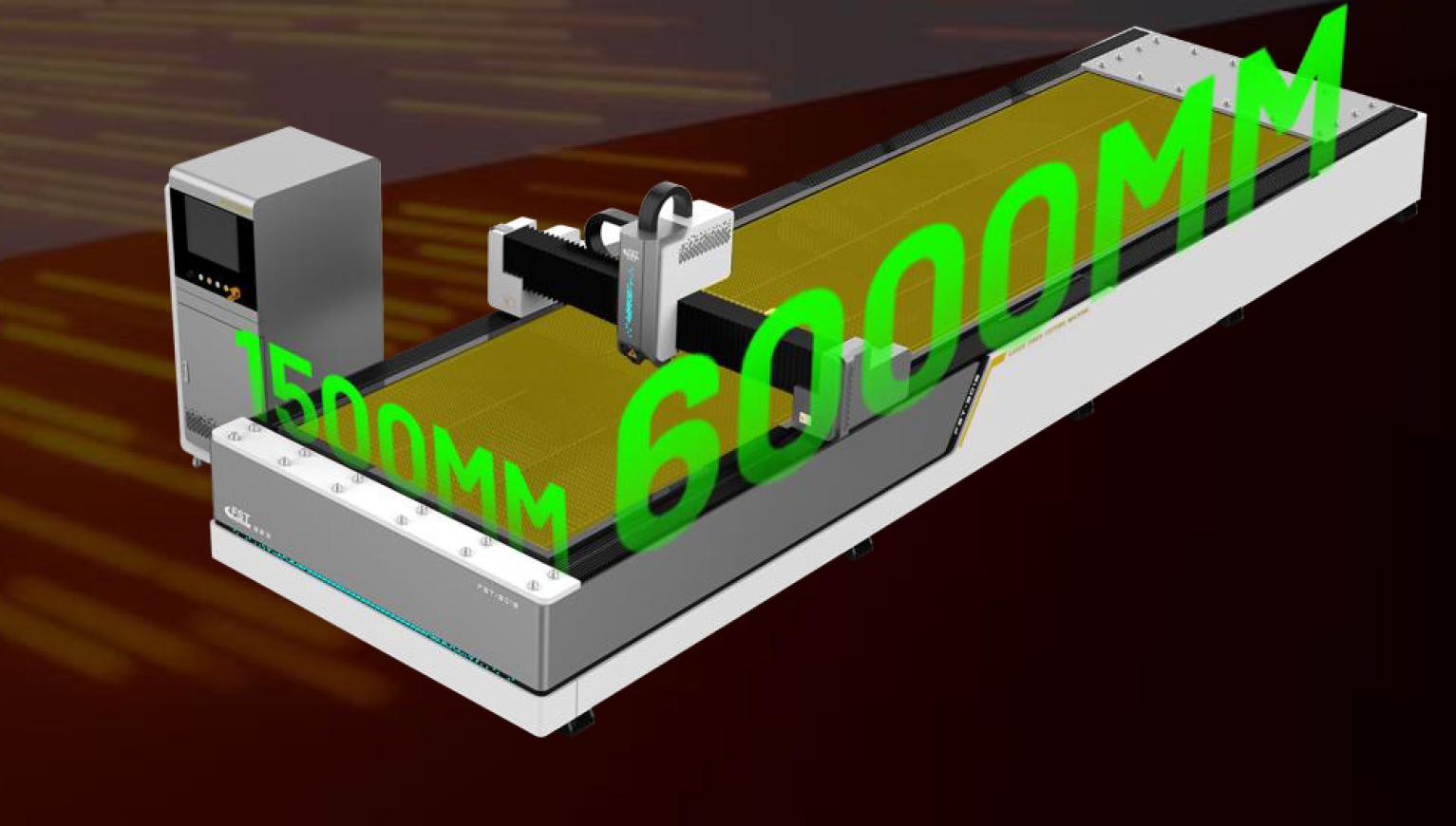

Oversized processing format

The maximum processing size is 6000mm * 1500mm, with almost no excess material and no additional cutting paths or micro connections, saving materials and improving production efficiency.

Subdivided Fluid Domain Dusting

The smoke exhaust device automatically senses the laser cutting position to open precise smoke exhaust, closes the non-cutting area for smoke exhaust, fully enclosed smoke control, increases suction, and removes smoke to the greatest extent.

Higher material utilization rate

More flexible layout, software has more space for optimal layout, and can easily handle parts with long or irregular combinations.

Replaceable Independent burn-proof sheet metal

Reduce the erosion of slag injection on the bed and improve the life of the bed.

Energy conservation and environmental protection

Because of the high energy conversion efficiency and low energy consumption, it can not only reduce processing costs, but also achieve environmental protection and energy saving.

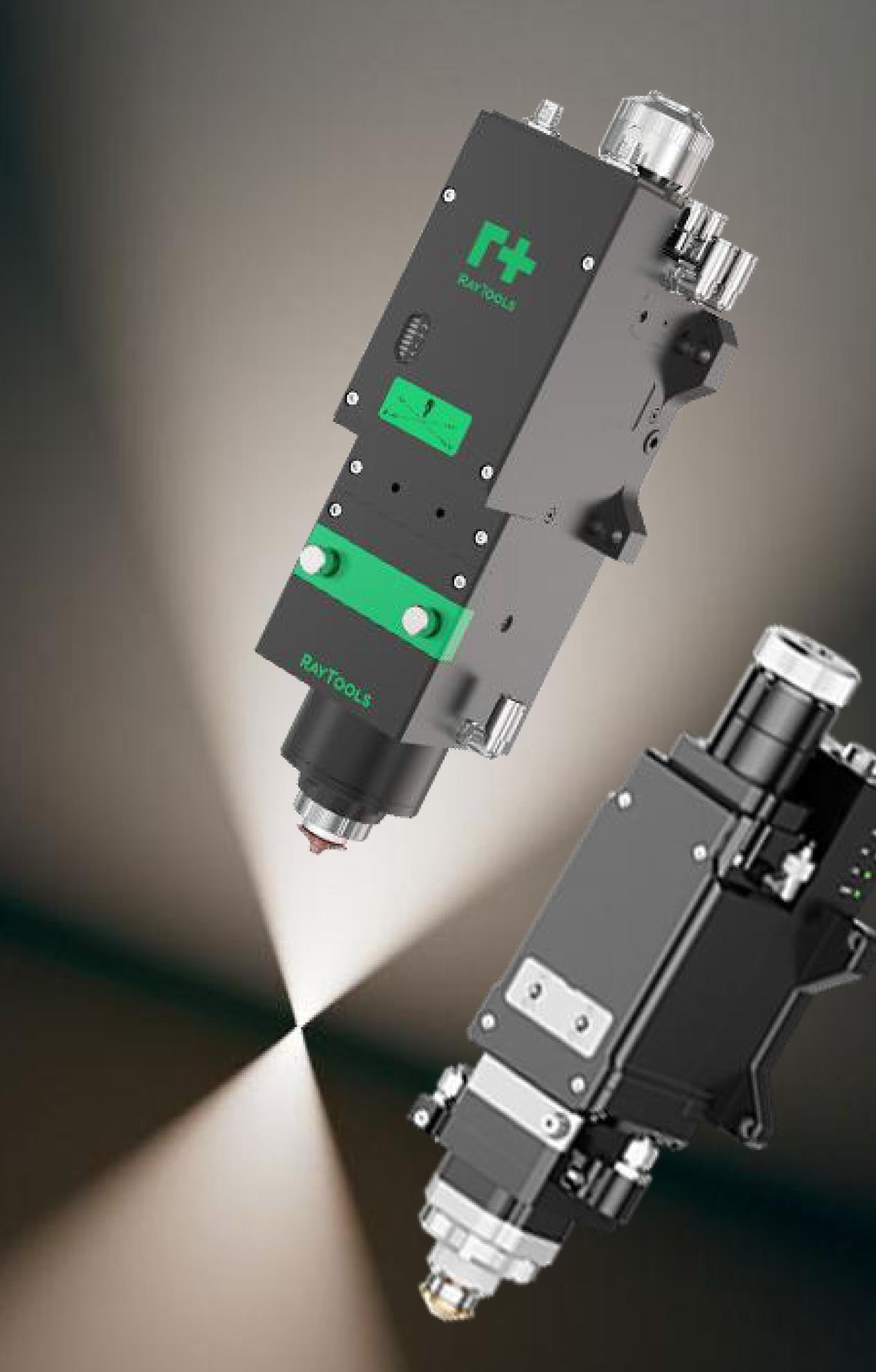

*Multiple Protection3 protective lenses , highly effective collimating focus lens protection.2-way optical water cooling extends the continuous working time effectively.

*High-precisionTo successfully avoid step loss,a closed-loop stepping motor is used.The repetition accuracy is 1M and the focusing speed is 100mm/s. Dust-proof to IP65,with a patent-protected mirror cover plate and no dead angle.

*Various Brands Of Laser Head Are AvailableWe can provide all high quality laser heads . It has been tested by us for a long time.

*Mainly processing 6-meter boards: If your business uses a large amount of 1500x6000mm boards, choosing 6015 is undoubtedly beneficial as it can directly bring dual benefits of materials and efficiency.

*There is a demand for large-sized finished products: Your product itself is in the form of a long strip, such as elevator car wall panels, production line frames, and long ventilation ducts. 6015 can eliminate the welding and splicing process, ensuring overall quality and aesthetics.

*Pursuing scale production: Your order volume is large and stable, and you need to maximize the production capacity of a single equipment. The high efficiency of 6015 can significantly shorten the delivery cycle.

*Diverse material types: You often need to handle boards of different sizes, and the large format of 6015 provides unparalleled layout flexibility, making it easy to handle scattered orders of various sizes.

Professional cutting laser source. With high-quality beam quality, high light conversion efficiency, the light emitting mode is more conducive to achieving a good and stable cutting effect with high quality.

Multiple Protection 3 protective lenses , highly effective collimating focus lens protection.2-way optical water cooling extends the continuous working time effectively. High-precision Various Brands Of Laser Head Are Available We can provide all high quality laser heads . It has been tested by us for a long time.

The system is a CNC software for planarlaser cutting suitable for power ranges of 30kWand below, and it also supports EtherCAT bus servoand pulse servo. 1.NON-PERCEPTIBLE PERFORATION 2.INTELLIGENT OBSTACLE AVOIDANCE 3.VIBRATION SUPPRESSION 4.SUPPORT BATCH IMPORT

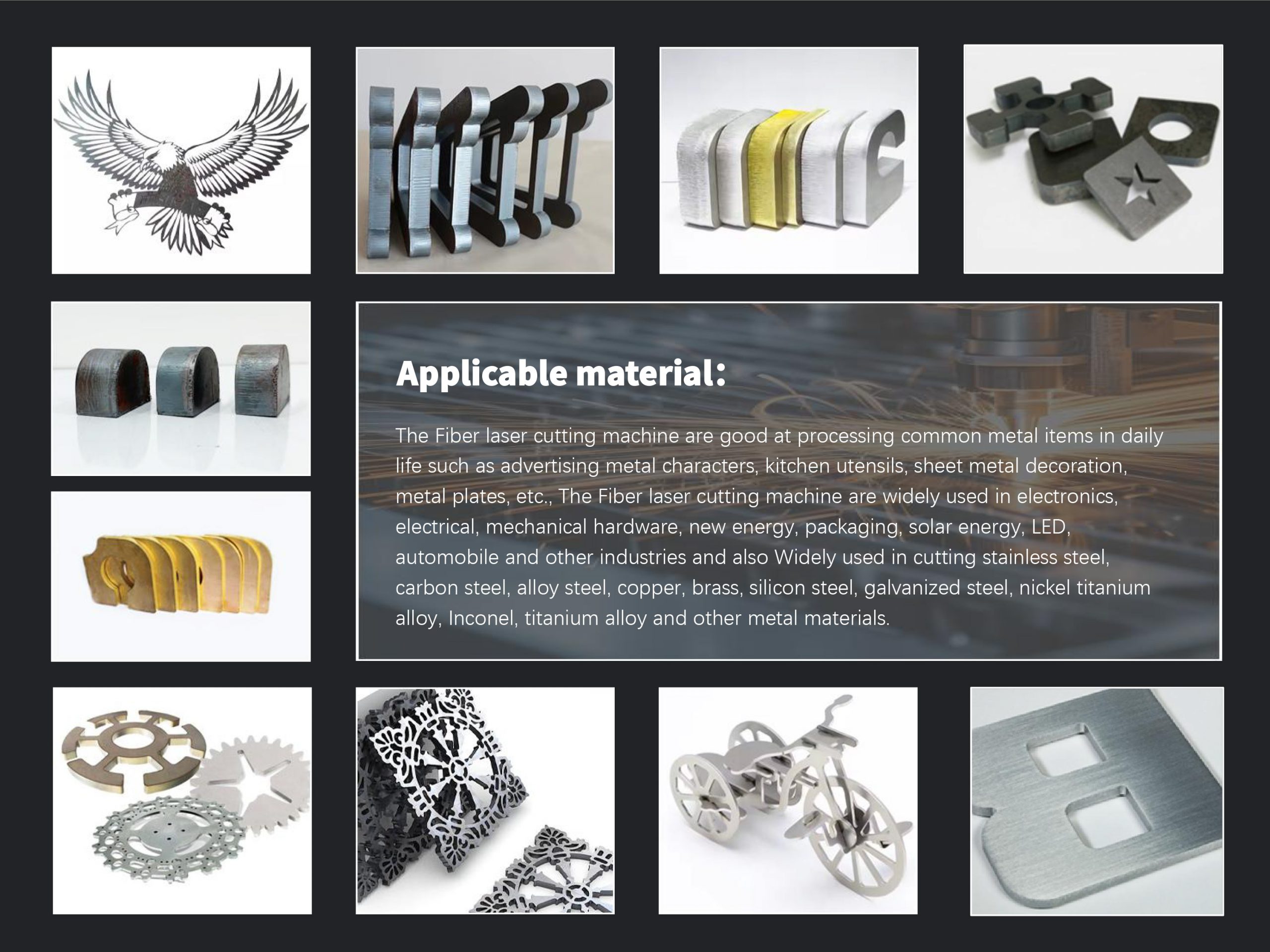

The Fiber laser cutting machine are good at processing common metal items in daily life such as advertising metal characters, kitchen utensils, sheet metal decoration, metal plates, etc., The Fiber laser cutting machine are widely used in electronics, electrical, mechanical hardware, new energy, packaging, solar energy, LED, automobile and other industries and also Widely used in cutting stainless steel, carbon steel, alloy steel, copper, brass, silicon steel, galvanized steel, nickel titanium alloy, Inconel, titanium alloy and other metal materials.

| Model | 6015/6020/8020/12020 |

| Laser power | 3000W 6000W 12000W 20000W(optional) |

| Laser wavelength | 1080nm |

| Fiber Source | Raycus Max Reci Bwt |

| Control System | BOCHU RAYTOOL |

| Compatible Software | AutoCAD CorelDraw etc |

| Graphic Format | DXF/PLT/LXD/GBX/NC code |

| Power supply Voltage | 380V 3PH 50/60Hz |

| Cooling method | Water Cooling |

| Working Life of Fiber Source | More than 100000 hours |

PROFESSIONAL LASER