2026-02-11 13:18:18

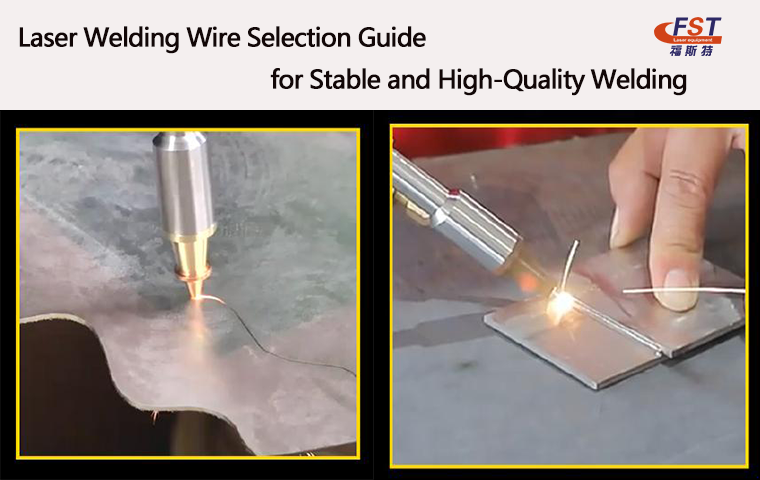

📌The right wire makes welding faster, more stable, and more consistent

When selecting a metal laser welding machine system, many users focus primarily on laser power, welding heads, or automation levels. However, one critical factor that directly determines weld quality is often overlooked — the filler wire.

In real production environments, the material, diameter, and feeding stability of the welding wire play a decisive role in weld bead appearance, mechanical strength, consistency, and even the long-term stability of the entire production line.

Based on years of experience in laser welding equipment development and on-site applications, Foster Laser has developed a practical and production-oriented approach to filler wire selection, helping customers achieve more reliable and repeatable welding results.

The Real Role of Filler Wire in Laser Welding

In laser welding—especially in laser wire-fed welding processes—the filler wire is far more than a simple consumable. It serves as a critical process control element:

✨Compensates molten metal and improves joint strength

✨Enhances weld bead shape and reduces underfill, edge biting, and defects

✨Optimizes weld microstructure to meet corrosion resistance and mechanical requirements

✨Increases process tolerance for joint gaps and assembly inaccuracies

During system design, Foster Laser has extensively optimized wire feeding rhythm, wire entry angle, and molten pool stability, ensuring that the filler wire actively contributes to weld quality rather than becoming a source of instability.

Filler Wire Material: Compatibility Comes Before Universality

The primary principle of filler wire selection is material compatibility with the base metal:

✅Stainless steel: matching stainless steel filler wires (e.g. 304, 316 series)

✅Carbon steel: low-carbon or alloy steel wires for better stability

✅Aluminum alloys: commonly 4043 or 5356 aluminum filler wires

✅Dissimilar metals: transitional filler wires selected based on service conditions

In real project deliveries, Foster Laser engineers evaluate material composition, joint structure, and operating environment to recommend the most suitable wire, avoiding situations where “the material matches, but performance does not.”

Operating Conditions Matter Just as Much

Beyond material matching, service conditions also influence filler wire selection:

📌Long-term exposure to humid or corrosive environments

📌Mechanical impact or high-temperature operating conditions

📌High aesthetic requirements for weld bead appearance

Under such conditions, filler wire strength, ductility, and corrosion resistance become especially critical.

For mid- to high-end welding applications, Foster Laser typically recommends high-quality industrial-grade filler wires with consistent chemical composition to ensure long-term process stability.

Wire Diameter: Coordination with Process Parameters Is Key

There is no universally “best” wire diameter. The correct choice depends on material thickness and welding parameters:

💎Thin sheets: smaller-diameter wires for precise molten pool control

💎Medium-thickness materials: medium diameters balancing speed and bead formation

💎Thick plates or high fill requirements: larger diameters for sufficient metal deposition

Foster Laser welding systems support stable feeding of multiple wire diameters. Wire feeding speed can be synchronized with laser power, effectively minimizing feeding interruptions, molten pool fluctuations, and spatter.

Filler Wire Quality Defines the Stability Ceiling

In many production cases, welding defects are not caused by equipment or parameters, but by inconsistent wire quality:

🔔Poor surface cleanliness → increased porosity risk

🔔Unstable chemical composition → inconsistent weld strength

🔔Poor roundness tolerance → unstable wire feeding

For this reason, during commissioning and customer training, Foster Laser strongly recommends using filler wires with stable composition and high surface cleanliness to fully utilize the performance of laser welding equipment.

Equipment × Filler Wire × Process: A Complete System

Even with the correct filler wire, insufficient equipment compatibility can limit welding results.

During welding machine development, Foster Laser focuses on:

Precise coordination between wire entry angle and laser focal position

Dynamic synchronization of wire feed speed and laser output

Preset process parameters for different wire materials

This ensures stable weld formation, low spatter, and high repeatability across a wide range of materials and wire types.

Conclusion: The Right Filler Wire Unlocks True Welding Performance

Laser welding is a system-level process, not simply a comparison of power ratings or specifications.

When filler wire selection is properly aligned with equipment performance and process parameters, users gain:

🎉More consistent weld quality

🎉Higher production efficiency

🎉Faster return on investment

Foster Laser remains committed to real-world applications, providing not only stable and reliable soldadora laser welding equipment, but also professional support in filler wire selection, process optimization, and operator training—helping customers achieve high-quality, high-efficiency welding production.

👉 Interested in learning more about our laser cutting, welding, or cleaning machines? Feel free to contact Us:+86 15314155887—he’s ready to provide expert guidance and the ideal solution for your needs.